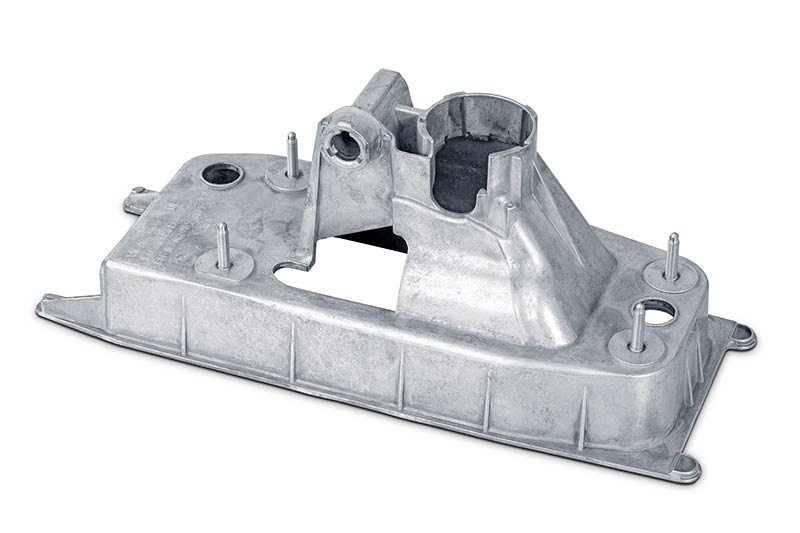

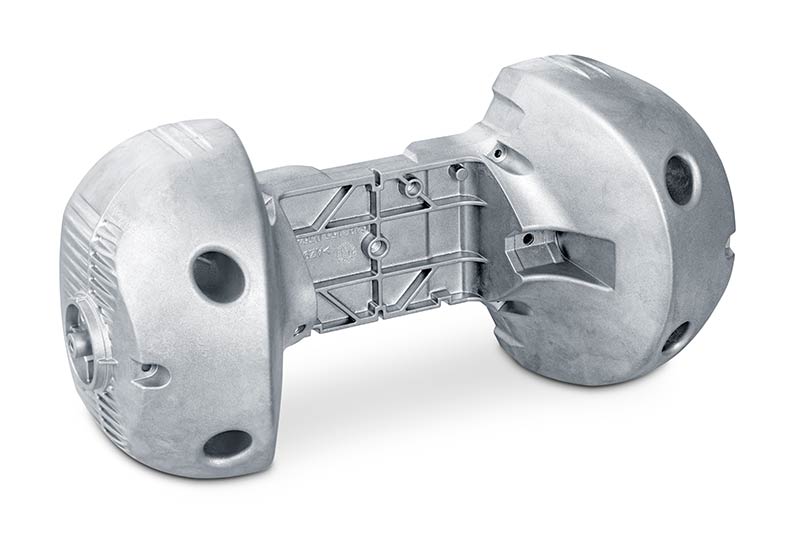

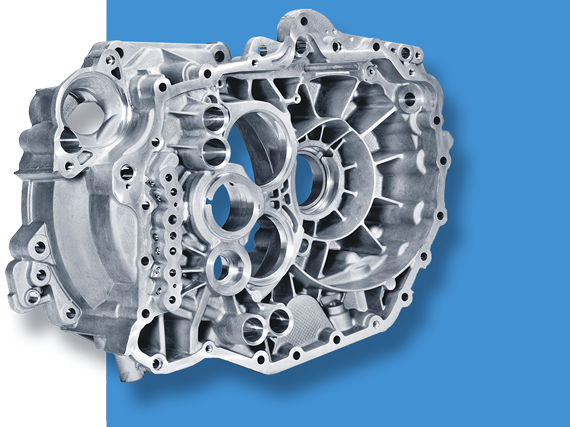

Die castings made of magnesium

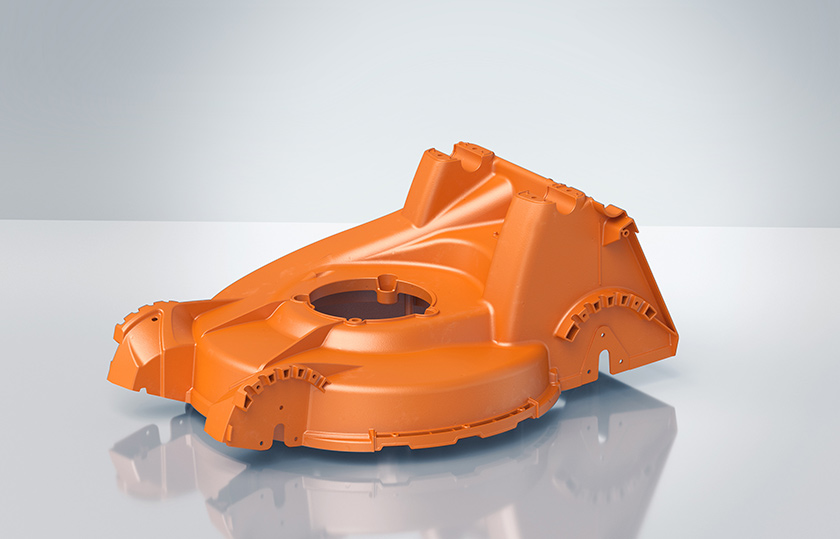

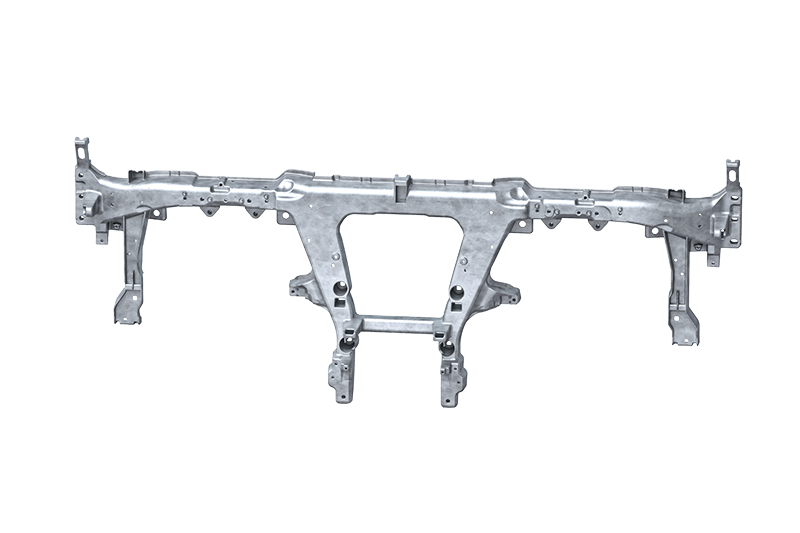

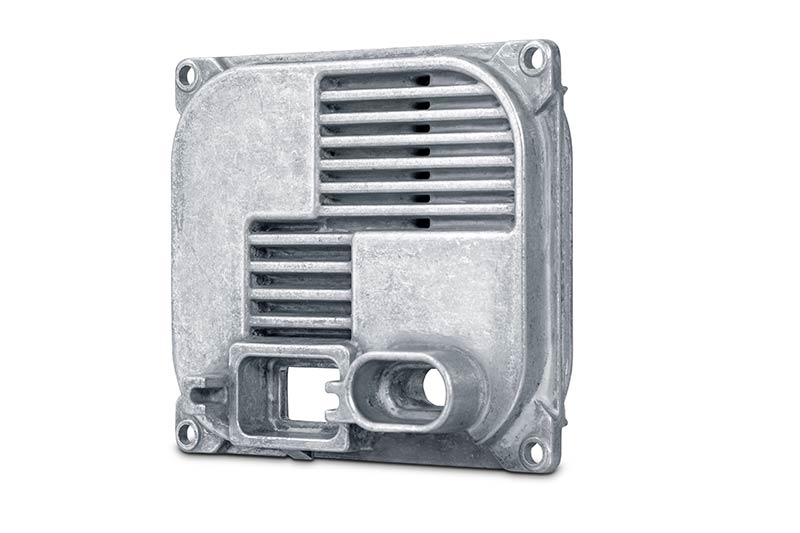

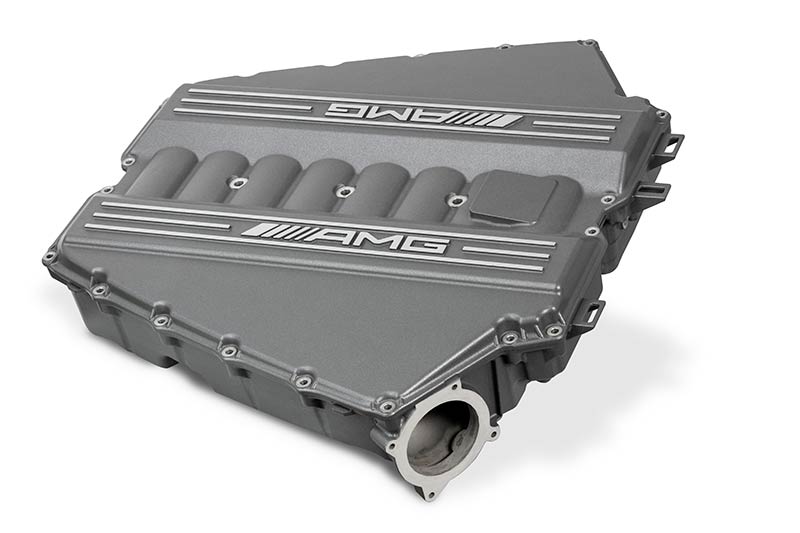

Aluminium is two-thirds lighter than steel, and magnesium is one-third lighter than aluminium. So magnesium products are well-suited for use in the automotive industry and especially in motor sports. Magnesium components are also characterised by increased damping, which can result in reduced vibration and noise emission. Among other things, there are gearbox and clutch housings, cylinder head covers, body parts, steering wheel rims, heat sinks, electronics housings and screen housings, which are produced using the magnesium die-casting process.

Contact us