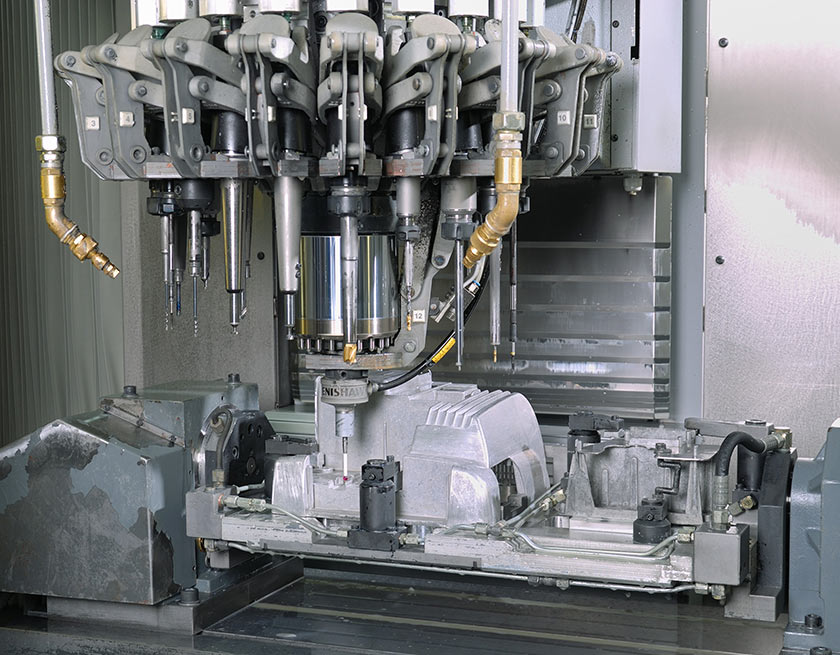

Post-processing of die castings

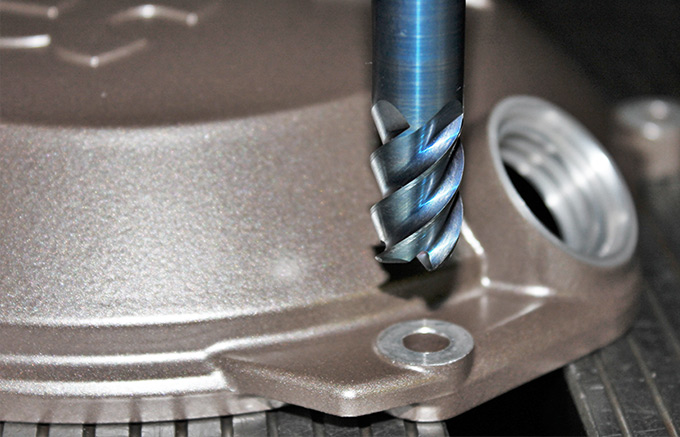

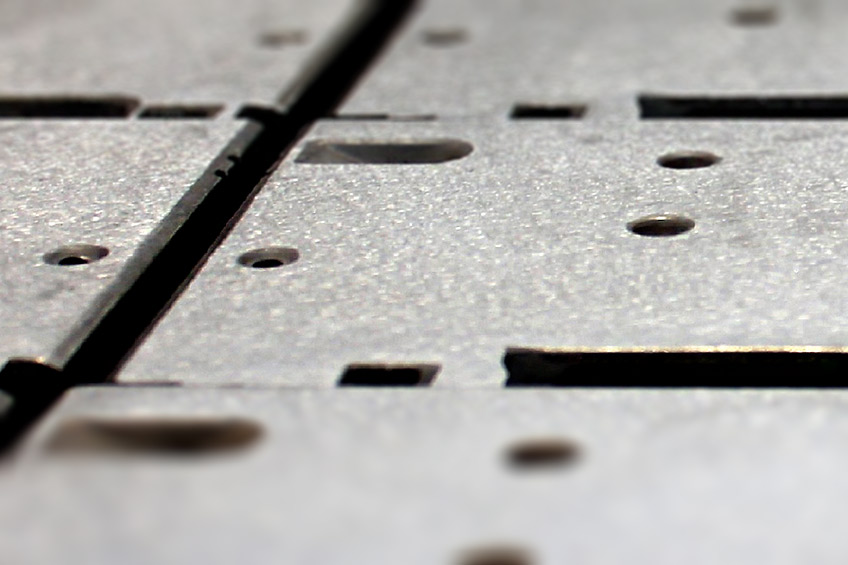

Already immediately after casting, our die-cast aluminium and magnesium parts have a high surface quality which, if necessary, can be further refined with mechanical finishing. We also take over all the processing steps with which we prepare the cast parts for further processing and proceed with the utmost precision and care. The castings machined in this way can then be fitted accurately and, after any necessary surface treatment, are ready for installation and delivery to our customers.

Castings machined with this approach can then be fitted accurately and are ready for installation after surface treatments, and can then be delivered to our customers.

Contact us