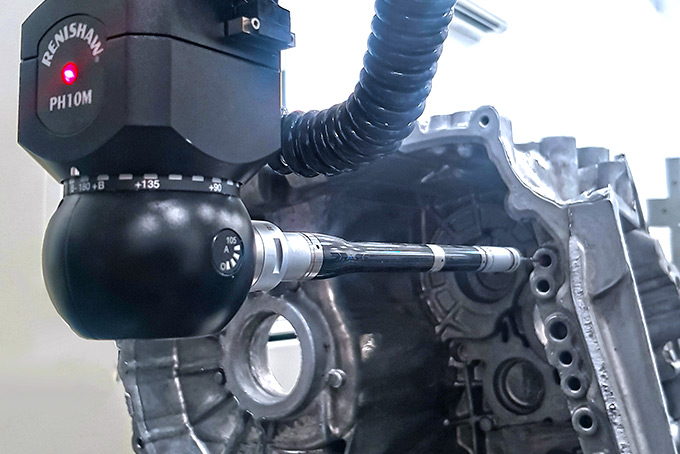

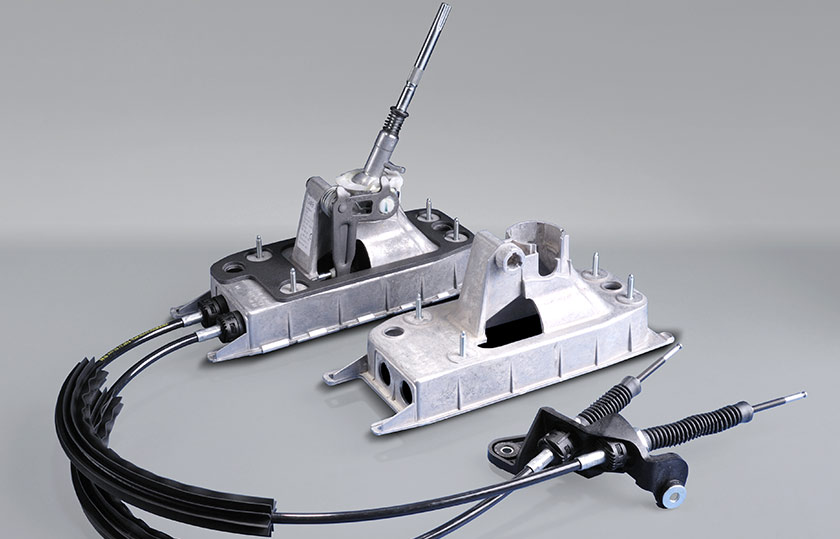

Material analysis

We only work with carefully tested raw materials. In order to ensure the requirements are met, we carry out thorough material analyses after the delivery of the goods as part of incoming goods inspection.

We only work with carefully tested raw materials and goods. In order to meet this demand, we carry out thorough material analyses during the incoming goods inspection after the goods have been delivered. We test the chemical composition of the respective material in accordance with standards thereby examining its suitability for further processing. Material analyses, so-called oven samples, are also carried out on an ongoing basis during the production process.

Contact us